By: George Efthymiou

1. Door layout

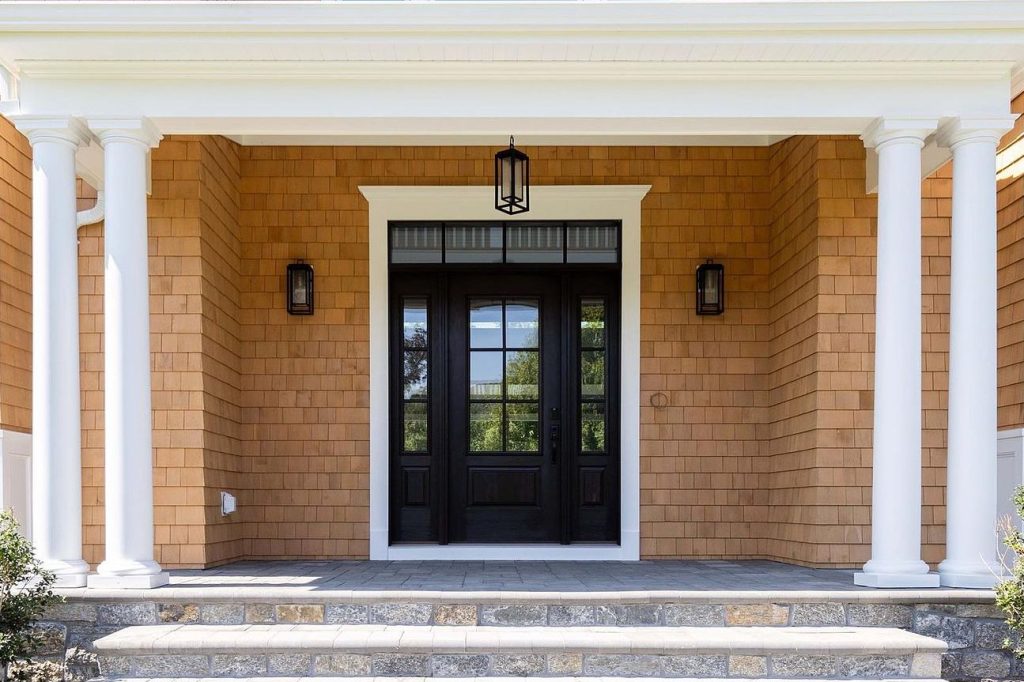

The first decision you need to make is whether you are replacing the existing door and leaving the layout the same. In other words, if you currently have a single door, are you staying with a single door, or looking to enlarge the entrance and add side panels or even a double door? Some of the available options are shown in the configurations section of the Fiberglass Entry Doors of our website. If you are exploring the possibility of changing the layout, you need to measure carefully to determine how much space you have available on the wall and what will fit into this space. Special attention should be paid both inside and out. Architectural transoms over the door may also be feasible if you have the proper height. If you are not sure how to measure or make the proper determinations, you may want to consult a door expert.

2. Choice of door panel material

Once you have made the decision on the door combination you would like to install in your home its time to move on to the type and model of door you want. The material with which your new door is constructed is the first important choice you need to make. Front entrance doors are generally constructed of three basic materials, namely wood, metal or fiberglass. Among these three categories there are many different fabrication methods and a great variety of qualities in each category offered in the marketplace.

Wood doors

Wood doors have been around ever since people started constructing houses a few thousand years ago. Currently there are many different choices offered in wood doors in terms of design and choice of wood species from which they are made. Practically a lot of types of wood are used for manufacturing entry doors including pine, fir, oak, cherry, mahogany, walnut and others. The construction of wood doors varies greatly among different manufacturers, but the basic design method utilizes rails, stiles and panel inserts to make a door panel. The stiles, rails and panel inserts can be either made of solid wood or from a basic inside core and veneer laminates on the exterior. The actual construction method as well as the wood species used will determine the quality and cost of the door panel. In general, hardwoods tend to make better quality, longer lasting doors.

Wood doors are not meant to get wet or be exposed to a lot of sunlight. It is therefore important to know before selecting wood as the material of choice for your door that the location where the door will be installed offers protection from the elements. This means that you will need a large overhang over the door, usually at least as large as the height of your door. Some wood door manufacturers recommend an overhang that is as wide as one and a half times the door height. In the case of a standard seven-foot-tall door the overhung may need to be approximately 10 feet long. If you do not have the proper overhung over a wood door, it is unlikely that the wood door manufacturer will offer any type of meaningful warranty. In addition, you need to consider the exposure of the door to sunlight that may reach the door. Southern and western door exposures allow for a lot more sun to reach the door.

The reason most people would consider buying a wood door is so that they can stain it and bring out the beauty of wood. This means applying a wood stain and several clear coats of polyurethane to protect the stain from the harmful ultraviolet (UV) rays in the sunlight that hits the door. Essentially the door is finished like a piece of furniture. A stained wood door is therefore a beautiful piece of furniture, where half of this furniture is inside the house and protected from the elements and the other half of this furniture is outside and exposed to the extremes of temperature, rain and the sun. When you look at your new wood door as a piece of furniture that remains outside, it is not hard to imagine what kind of challenges you face to make sure the door does not deteriorate very fast.

If you are considering a wood door and you plan to paint it a solid color, then there are much better options than wood. The only good enough reason to purchase a wood door that will be painted a solid color is when the door panel design that you absolutely want is not available in a fiberglass door. Perhaps the biggest advantage of wood doors is that they can be crafted in an endless array of styles.

Wood doors come with several challenges that you should consider before making the decision to choose a wood door for your home. These challenges include the need for timely maintenance to make sure your wood door does not deteriorate. Application of a new clear polyurethane coat will be needed often to protect the wood stain finish. If you allow the protective coat to deteriorate it will lead to failure of the finish and eventually failure of the door structure. Other potential problems include the cracking of the wood panels or the rails and even rotting of the wood and warping of the door panel. If the stain finish deteriorates but the door structure remains intact, your wood door can be sanded down and refinished again. Another problem that can arise is the expansion of the door, usually after the wood absorbs moisture. When this occurs, the door hits the frame and does not close properly. To resolve this problem, you usually need to plane one side of the door to make it fit in the frame. Wood doors in general will therefore require a lot of tender loving care and maintenance.

Another potential drawback of wood doors is that they are the least energy efficient choice among the different door material options. Wood doors are not insulated and therefore not energy efficient. Solid insulated fiberglass or insulated metal doors are at least five times as energy efficient as solid wood doors (from energy.gov). Another potential problem with wood doors is air infiltration around the perimeter of the door panel. Even though most wood doors have a weather strip where the door panel contacts the doorframe, air leakage is an issue because wood doors expand, contract or warp with changes in temperature and humidity and it prevents them from making proper contact with the weather strip.

Metal Doors

There are two main categories of metal doors. The most common category is what is known in the industry as steel doors. They get their name from the thin metal skin used on either side of the door panel. Around the perimeter they usually have a small wood rail approximately one inch wide to which the metal skin surfaces are attached. In the center they contain some type of insulation typically blown in polyurethane. The construction of steel doors is similar to the construction of a large variety of fiberglass doors. Steel doors have been popular 20 to 30 years ago. They were favored over wood doors because they are much more energy efficient that wood doors. When a homeowner chose a steel door over a wood door, they gained a lot in energy efficiency but gave up a lot in terms of door strength. Steel doors are not very popular right now primarily because of their tendency to dent when they get hit even at low impact, for example by the contents of a bag of groceries. In addition, homeowners find better options than steel doors when they explore fiberglass doors.

The second category of metal doors is generally known as wrought iron doors. They are constructed of heavy wrought iron tubes and bars. They are very strong, and they come in a variety of decorative iron designs. They are popular with certain types of homes, and they are relatively inexpensive. Their biggest drawback is that they are the least energy efficient doors that exist on the market. Because they are made using solid metal, there is absolutely no insulation barrier between the interior and the exterior of the door. If you live in a climate where the temperature in the wintertime goes down to 30° Fahrenheit outside, when you touch a wrought iron door from inside the house, the temperature you feel will be very close to 30°. The biggest problem this creates is not that your hallway and your home would feel very cold, but rather the fact that moisture inside your house will start condensing on the door and running down and eventually will freeze and create frost or ice on your door inside the house. In addition, these wrought iron doors are not very well weather striped and the result is a great amount of air coming through the door. This will be a big problem both in the winter as well as the summer. Wrought iron doors are more appropriate for milder climates like Florida, Texas or Arizona. They are a very poor choice for the middle and northern states. Long Island is not the place for a wrought iron door unless you do not care about all the inconveniences they create.

Other problems associated with wrought iron doors involve the development of rust at most of the locations where the different pieces are welded together.

Fiberglass doors

Fiberglass is currently the most popular material for door construction. Just like wood doors, fiberglass doors are constructed in many different ways and the result is a great variety of qualities available in the marketplace. There are however three basic components that determine the overall quality of any fiberglass door. The most important component is the structural one. In other words, the side rails and the top and bottom rail will determine how strong and durable the fiberglass door will be. Unfortunately, the average person cannot determine the quality of any fiberglass door when looking at an intact panel. To be able to tell the structural quality of a fiberglass door one needs to cut it up and look inside. The width of the side rails in fiberglass doors can vary a lot, from about 1” to 4-1/4”. In addition, a lot of fiberglass doors do not have the same size rails on both the hinge as well as the lock side. The slimmer rails are found in entry level, builder quality doors that are designed to be inexpensive and they are sold in many home improvement stores and lumberyards. The heavy rail doors are constructed in a manner similar to many wood doors and they feature stronger rails made out of LSL engineered wood. Doors with these types of heavy-duty rails are sold by specialty door manufacturers and retailers.

The second component that determines the quality of a fiberglass door is the fiberglass skin panel that goes on each side of the door. The fiberglass component of the doors differs in design detail, thickness of the panel and detail of the wood grain that it simulates. Lower quality doors utilize thinner fiberglass skins that are smooth or with less detail of the wood grain and panel design they represent. Fiberglass door panels are made to simulate several different wood grains and looks, including oak, mahogany, cherry, fir and others. They also include smooth surfaces that are designed to simulate a wood door that is painted a solid color. Specialty door manufacturers and retailers offer more choices as well as a much higher quality and realistic looks.

The third component of the fiberglass door panel that determines the door quality is the type of insulation that is placed between the door rails and the fiberglass skins. The better-quality fiberglass doors utilize blown in polyurethane insulation, which solidifies and becomes an integral part of the door panel structure. The polyurethane insulation provides a higher R-value to the door panel, making it more energy efficient. The alternative insulation used by some fiberglass doors is a sheet of polystyrene that is simply dropped in the cavity between the rails and the fiberglass skins. It does not provide any structure to the door panel, and it is much less energy efficient than polyurethane.

Fiberglass doors can be either painted or stained, just like wood doors. Both paint and gel stain attach differently on fiberglass than wood. Fiberglass is nonporous and more stable than wood and the paint on fiberglass is in general more durable than on wood. Fiberglass doors that are gel stained to look like wood doors have the same problems with the durability of the gel stain finish as wood doors. The finish on gel-stained fiberglass doors deteriorates with exposure to uv light from the sun just as it does on wood doors. Unlike wood doors however, that can be easily sanded down to remove the old stain and be refinished with new one, fiberglass doors cannot be sanded down. If they are sanded, then the grain look in the fiberglass skin is damaged or removed and the newly stained door does not look as good or realistic as the original.

Staining of a fiberglass door to make it look like a wood door is not recommended. There are other ways to make a fiberglass door have the look and feel of a wood door without having to use gel stain. There are ways to paint a fiberglass door and make it look like a wood door. This process is more difficult and more elaborate than the simple staining method. The result however is a finish that is durable, easier to touch up scratches of the paint and very easy to repaint the door when time comes for refinishing.

3. Choosing the look and feel of your new door

a. Amount of glassOnce you have made the decision on what type of material your new door panels will be made of, it is time to move into design mode. You have already decided on a layout, meaning single door, double door or door with side panels. Now it is time to decide how much glass you would want on your new door. The amount of glass you put on your door will be one of the factors that will define the overall final look and feel of your new door. It is important to keep in mind the style you are aiming to get at the end of your selection journey. Are you looking for your new door to be traditional, modern, transitional or timeless? All the potential options of the amount of glass you can choose for your door are also shown in the configurations section for Fiberglass Entry Doors on our website. There are many choices, and it could get a little overwhelming, however there are other factors that may help to narrow you selection options. Glass not only affects the look and feel of a door setup, but it also determines how much light will come into your foyer. Keep in mind that how much privacy you will have with your new door is not entirely a function of the amount of glass. It will depend more on the type of glass you choose to put on the door and not the size. If you prefer to get a lot of light through your new door and have a lot of privacy you can achieve both objectives.

b. Type of glass designThe second selection that you must make after deciding on the amount and shape of glass you want on your door is the type of glass that will be placed in the designated spots on your door. At this stage of the selection process the choices are numerous. The simplest of course is plain clear insulated glass. There are also many choices of textured glass that provide different looks as well as various privacy levels. Whether you prefer clear glass or some sort of textured glass, you can also add either grids between the insulated glass (GBG), or simulated exterior divided lights (SDL’s), to introduce another design element.

A still very popular choice is what is called caming glass designs or otherwise known as leaded glass. There are hundreds if not thousands of choices in this category with variations of the color or finish of the caming. These glass panels consist of an insulated glass unit with three layers. The two outside layers of the insulated glass unit are pieces of clear tempered safety glass, and the center unit contains the caming design. The styles vary considerably in look and feel, and they can be very traditional looking or very modern looking or in between.

Another class of door decorative glass is what is known as wrought iron decorative glass. It is made up in a similar way to caming glass except a wrought iron design is placed in the middle instead of the caming design panel. Wrought iron glass designs can make a fiberglass door look like the solid iron doors without having to worry about all the problems that solid iron doors have in colder climates.

c. Door colorThe next selection to be made is the door color. The color can be the same inside and out or it can be two different colors. The whole door unit including the panels and frame can be the same color or the panels can be one color, and the door frames a different color.

One still popular choice for color on fiberglass doors is what is described as a ‘wood look’ door finish. There are two ways that this can be achieved. The original way, which is still used today by many companies is to stain the fiberglass door panel as if it was a wood door. Instead of using standard absorbing wood stain they use gel stains. The process is like the way a wood door or a piece of furniture would be finished. The problem with this approach is that unlike furniture that we usually keep inside the house and are protected from the sun and the elements, doors end up with one of their sides being inside and protected and the other side being outside and exposed. The exterior of the door, in most cases is exposed to the harsh uv rays in sunlight as well as to the whims of the weather. Stained fiberglass doors do not fare very well if they are exposed to sunlight on any part of the door. The biggest problem however is not just that the finish will weather relatively fast but rather that it is almost next to impossible to refinish a stained fiberglass door when the stain fails. It is very difficult to clean the door surface in order to do anything with it.

Luckily there are other ways to get a fiberglass door to look like a stained wood door without having to use stain. The best one is to paint the door using certain techniques that will result in a ‘wood look finish’ using only paint. This process can result in door finishes that are more fade resistant than stain by using special paints that are highly UV resistant.

Fiberglass doors can be painted a solid color, and the options are limitless. Any color from a color swatch can be matched with appropriate paint to give you the precise color you desire. Some of the popular colors right now include black, various greys and blues and of course white.

When selecting the color for your new door your guide should be the colors that are found next to the door both from the inside and out. The idea is to select a door color that complements and coordinates with whatever is around the door.

d. Lock set or door hardwareThe last component that is left to select to complete the design of your new door is the hardware. Because you have by this stage given your door a certain look and feel, based on the selections you have made so far, the hardware selection becomes a little easier. You are looking for something that complements what you have already assembled. You need to focus on selecting locks whose shape works well with your door and a finish that is complementary to both the glass and color of your door as well as other things like light fixtures located close to the door.

So far, we have talked about the choices you have available to select from in terms of deciding on the door layout you want or can fit on your house. We have also covered the material with which your door can be made from and the options you have available in terms of the amount and type of glass you can use in your new door. We explored options for colors or finishes as well as guidelines for selecting them and how to go about choosing a new lockset. All we have covered so far is just one side of the coin in your quest to get a new front entrance door. Equally important is deciding on the quality level of door you desire to avoid making a serious mistake and wasting time and money. The look of the new door you want has nothing to do with the quality level of the door you will ultimately purchase. It is not easy to know if a door you are looking at is of good quality. The definition we use of quality, for all practical purposes, relates to the energy efficiency and durability of the door in question.

Stay tuned for our follow up article on how to recognize a quality build door.